There are two major types of broaches: internal and external. Internal broaches cut a hole at the centre of the workpiece, whereas external broaches cut splines and slots on the surface. External broaches are generally much faster than internal broaches because they do not require a starting hole. They are also more economical, as they can be made from a solid piece of steel, and they can be modified to change the shape of the workpiece.

Internal operations shape a round hole using a push or a pull broach. The former offers longer cut lengths, particularly when using a square or hexagonal part. Other internal operations include rifling and keyways. In general, external operations produce more accurate dimensions. They can be used to create flats, keyways, contoured surfaces, and gear teeth. Regardless of their use, broaches can produce complex shapes.

Broaches are generally made from high-speed steel or carbide. High-speed steel is a cheaper alternative to carbide, and it’s hard enough to retain its sharpness for a long time. However, carbide is the most expensive material, and will break quickly. Therefore, tungsten carbide is not widely used for broaches. These tools are typically crafted for high-volume production. A good quality broachis one that lasts for years and decades of use.

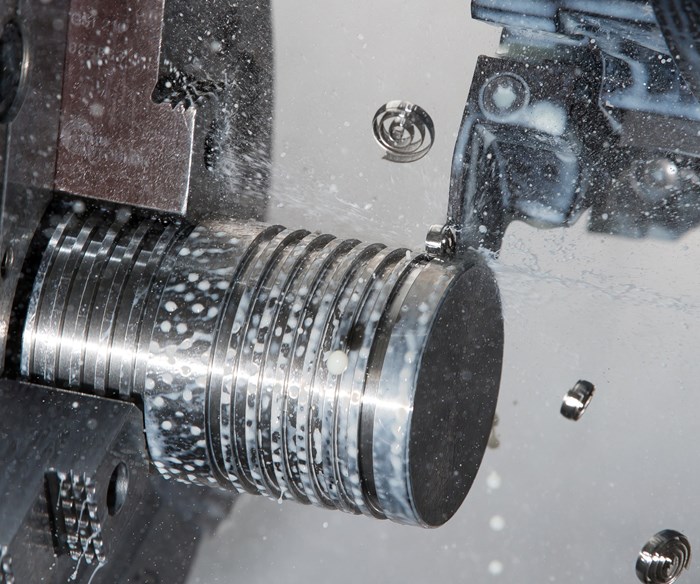

A broach is a long tool with multiple teeth. Its multi-tooth design enables it to finish a rough surface in one stroke. Broaches are made up of several teeth, each of which cuts a predetermined amount of material in a specific location. The total depth of material removed in a single stroke depends on the number of teeth used. A broach can produce parts with an excellent surface finish and can compete with other processes such as boring and milling.

A well-crafted broach can cost a lot. Custom-designed broaches are expensive, but they’re worth the money if you need to work with precision. Broaches are a great way to save money and make a high-quality part, and they don’t have to be complicated to make. And since they’re cost-effective, you may find yourself using them more often than you thought! You might even want to consider a budget-friendly broaching machine. Shop broached from Somma Tool.

The broaching process is an ancient machining method. Today, it is a vital part of many industrial operations. It is particularly important for the aerospace and automotive industries because of its accuracy and complexity of cutting. Broaching can be done on a variety of metals, with preferred metals having Rockwell C hardness between 26 and 28. The process is also very precise, and you can use it for small quantities or limited shapes. In other words, it is the best choice when you want to work with small, low-volume parts.

Another type of broach is known as pull broaching. Pull broaching holds the workpiece in place while the broach is being pulled through. Unlike push broaches, this method requires a special head that is used to pull the workpiece through. The tension that the broach applies when pulling makes it more efficient. In addition, pull broaches can be used to complete internal broaching. They are long and have lots of teeth that offer a long cut. Furthermore, they can be used horizontally, vertically, or up and down. Automobile cylinder blocks are often faced flat using this method.

Another type of broach is the keyway broach. This tool is designed to create holes with a keyway in one pass. It has several teeth and a bar-shaped design. It is also self-supporting, and can be sharpened a number of times. The keyway broaches can be sharpened several times, which prolongs the life of the tool. They also have sets for increased efficiencies. These broaches are ideal for making precision keyholes.

There are two different types of surface broaches. The slab broach is designed for flat surfaces, while slot broaches are designed for cutting slots of different sizes. This type is more efficient than milling because multiple broaches can run through a part simultaneously. In addition, there are contour and surface broaches, which are used for cutting irregular and concave surfaces. When choosing between a slab broach or an surface broach, you must consider how your part will be used.