In order to make a CLT wall panel look its best, proper CLT detailing is essential. The CLT Handbook provides detailed information on CLT detailing. Inexperienced engineers typically rely on exposed steel hardware, which is not only unattractive, but also performs poorly in fire. Exposed steel hardware is also not appropriate for structures requiring a fire-resistance rating. Exposed screw heads and cleats are not the best choice for such applications.

CLT can be used in a variety of construction applications, including multi-storey tall wooden buildings. Prefabricated wall and roof sections allow for taller floor plates and girders, and the CLT material can be used to support load-bearing stairs and elevator shafts. Because CLT lumber is normally oriented upwards, it can contribute to the aesthetic look of a building. CLT wall panels can be installed on a construction site in any season, making them an excellent choice for complex structures.

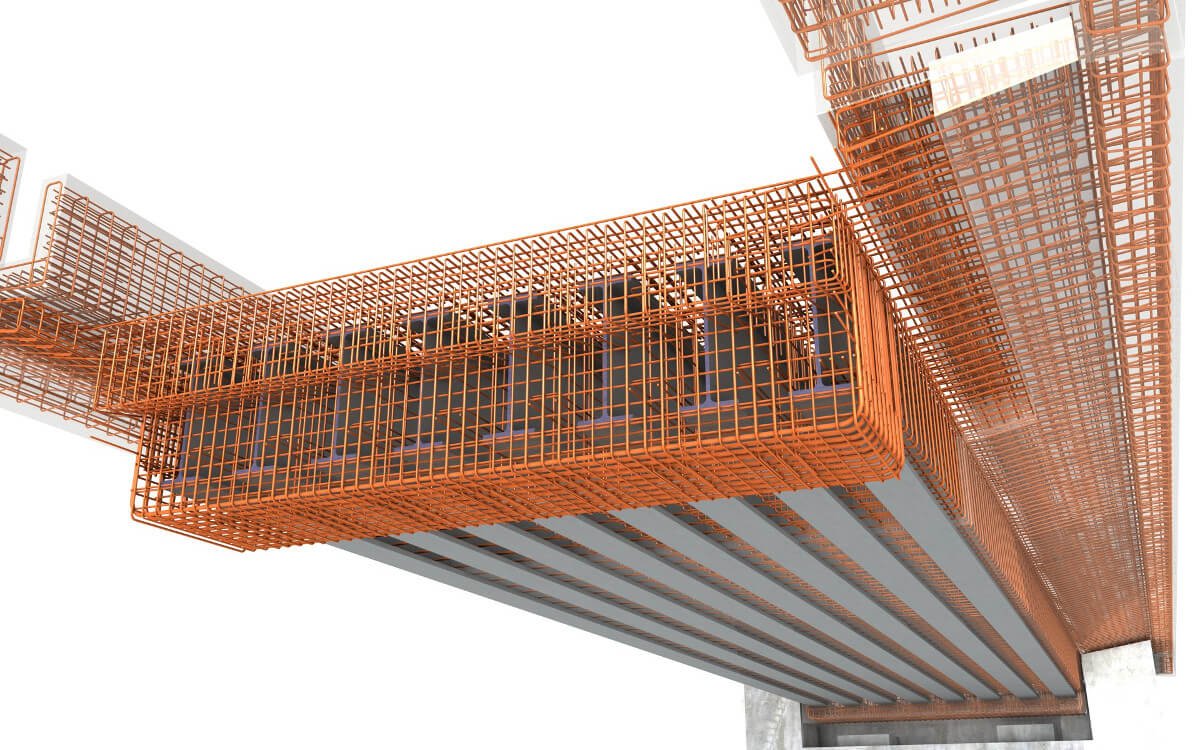

CLT panel detailing can take several forms, including panel lay-up, defect removal, and final quality control. CLT fabrication takes place in a factory setting under strict quality control requirements. Get Bridge Detailing now. To meet these high standards, fabricators rely on building information modeling (BIM) technology and precision fabrication. It is important to understand the details and the process of fabrication before deciding on a particular design. When choosing a CLT detail, keep in mind the design intent and budget constraints of the project.

Cross-Laminated Timber (CLT) is a type of engineered wood panel product made from multiple layers of structural composite lumber. CLT is typically used in floors, walls, and roofs. Because of this, CLT detailing is critical in mass timber structures. Properly detailed CLT connection details allow for cost-efficient, easily-fabricated structures. By contrast, poorly-designed CLT detailing can result in a structure that is overly expensive and difficult to build.

Depending on how intricate the details are, CLT can be used to produce an impressively high-quality structure that meets a client’s requirements. It is also an eco-friendly material, using renewable wood as a source. It is also recyclable, requiring no fossil fuels for production. It has been widely used in large construction projects, as a base for tractors in unstable terrain. It has even been used in small constructions, resulting in unique, eye-catching designs and structural strength. Its enduring qualities have led to the development of skyscrapers made of CLT.

Depending on the region where CLT is to be used, a water-repellent coating can be applied to the panels. Water-repellent coatings should have a moderate vapor permeability, allowing the CLT panels to dry out. However, pre-applied coatings are especially beneficial at the edges of a panel. End-grain wood is the fastest place for moisture to enter. Get in touch with Dowco to get Rebar Detailing. Furthermore, water-repellent coatings are not effective for prolonged exposure.

Pre-applied WRB/AB membranes are another way to reduce exposure to water. These membranes help to manage water during the construction phase and help CLT remain structurally sound. They also provide additional protection against ponded water. These membranes are a good choice for taller buildings. The use of pre-applied membranes can help to reduce the construction schedule. While membranes may not be necessary for tall buildings, general water management strategies are vital for a long-lasting building.

While the CLT panel and the panel underlayment are crucial for protecting the building against weathering, the roof underlayment is an important part of a successful CLT roof. A CLT panel that is unable to shed water during construction may require a membrane that is vapor permeable. While ponded water will slowly pass through the membrane, it will not cause any water to leak through the membrane over 24 hours.

Pre-installed membranes are an additional important consideration for CLT panel protection. In addition to pre-installation of membranes during the fabrication process, moisture protection is also essential during shipping. However, depending on the climate and season, additional protection is required. This includes slatted metal and mesh panels that will reduce the chance of moisture penetration to the panels. Ensure that the CLT detailing is consistent throughout the entire structure and ensures a smooth appearance.